Don't have an account?Make your registration.

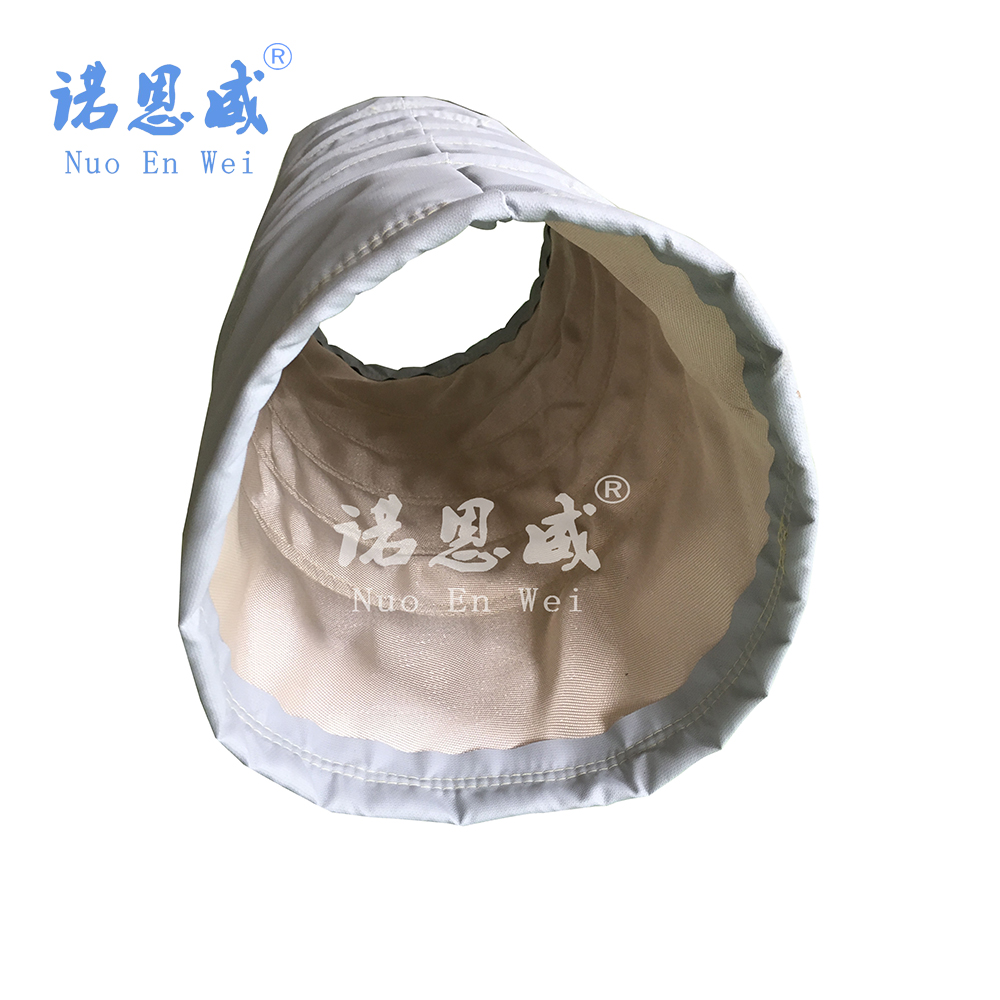

International.According to FabricAir, logistics, installation and maintenance are the 3 main problems that can arise regarding the proper functioning of air ducts. Pvc Ventilation Duct

For the brand, air distribution systems are essential for each building.However, before and after installation, many questions or problems may arise and each step must be thought out to the last detail.

“Proper planning and selection of the right air dispersion system can help avoid wasted time and resources, reduce costs and avoid operational disruptions.Therefore, from logistics to maintenance, air distribution systems require a lot of planning and, more often than not, conventional solutions pose some difficult problems that have better alternatives.”

Problems with conventional solutions FabricAir indicates that conventional metal ducts are heavy and take up a lot of space.“Some systems may require a lot of metal conduit, which would require transportation in large trucks.Additionally, there is a high probability that the ducts will not be installed immediately and will need to be stored, most likely outside due to limited space.”

In that sense, outdoor storage could affect the cleanliness of the ducts and, if the ducts are not cleaned properly, accumulated dirt and debris would move to the already cleaned or prepared areas.

“Metal ductwork is extremely heavy and requires many special tools, skilled workers and heavy machinery to install.The installation process is also time-consuming, as it takes 30 to 40 minutes to install a meter length of conduit.”

Furthermore, the company notes that in large facilities where there may be hundreds of meters of ductwork, metal ductwork can add significant time to the construction or renovation process.

“Maintenance of metal conduits is also very complex.Both externally and internally, ducts can accumulate dirt and bacteria, and some companies must maintain air distribution systems due to strict hygiene requirements.”

For proper maintenance, FabricAir notes that “ventilation systems may need to be turned off, which could mean stopping production.”

Lighter, faster and simpler: “it's all in the fabric” Considering the problems associated with the transportation, installation and maintenance of metal ductwork, FabricAir assures that fabric air dispersion systems can be an effective and, in most cases, superior alternative.

“Its natural properties of flexibility and lightness make fabric ducting one of the best alternatives to metal in the entire HVAC industry.”

The company indicates that one of the greatest advantages of textile ducts is their lightness and ease of packaging.“Unlike metal, fabric ducting can be transported very easily as it is densely packed in boxes on a few pallets.“Even for the largest applications, they can be shipped around the world without the need for transport trucks.”

Additionally, such fabric ducts are easy to store until the day of installation.The enclosed box ensures that the ducts remain clean and undamaged until installed and will not incur additional maintenance problems by bringing dirt and debris into facilities occupied by people or delicate machinery.

“When considering installation time, this is one of the best solutions, as the ductwork does not have to wait until the room ceiling has been prepared.”

Manufacturers can ship rails immediately, which arrive at the construction site in just a few days.“In addition, no special tools or equipment are required to install the rails.The duct pieces can be ready in a few days, and in about a week, just two people can hang the fabric ducts, resulting in an attractive, safe and smooth-running air distribution system.”

Simply put, FabricAir finds fabric ducting so easy to install that “even with limited experience, it takes about 10 minutes to install a single running meter.”

Now, regarding maintenance, the company explained that they require it, “however, it is significantly easier.“One of the easiest ways is to purchase replacement fabric ducts that can be replaced and the system can be up and running with less downtime and less effect on productivity.”

If replacement ductwork is not available, the system can be uninstalled, washed ductwork in a commercial washing machine, and reinstalled.“There is no need for specialized companies or expensive maintenance.”

Non-Standard Diameter Ventilation Duct In short, for FabricAir, fabric-based air distribution systems can save not only a lot of time, but also money and resources.That is, they are an “efficient and superior alternative to conventional metal HVAC systems that are incorporated into a growing number of applications with superior results.”