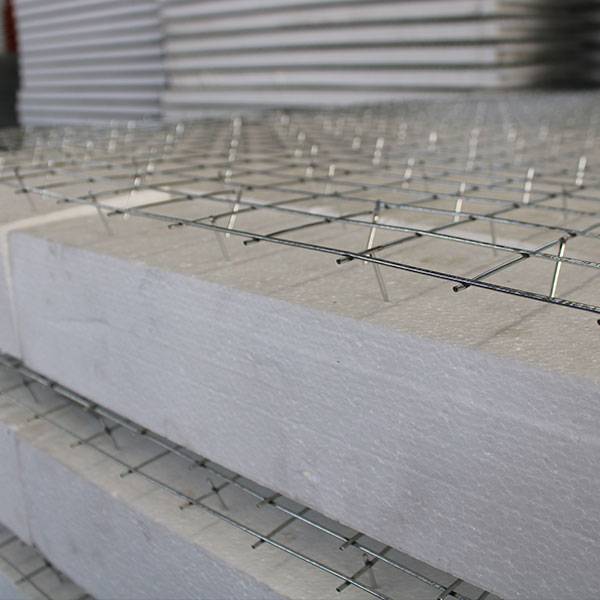

OctaFoam prototype – inside view | all images courtesy of Southeast University & ETH Zurich

The prefabricated foam components are assembled as dry masonry, and the interlock mechanism, inspired by the Abeille vault, enhances seismic resistance. The structure, made entirely of ceramic foam, features a rotated discrete grid, blurring the boundary between skeleton and infill. Oriented openings can be added, enhancing sunlight intake or framing specific views. OctaFoam, cut using a diamond wire saw from large recycled ceramic foam blocks, proves more eco-friendly than traditional bricks. The research team from Southeast University Nanjing and ETH Zurich employed a wire-cutting technique, inspired by stereotomy, for complex structures. The masonry mechanism aims to minimize components and wire-cutting trajectory, balancing design and economic production. OctaFoam incorporates two-scale architected porosity, optimizing material usage and offering superior structural and thermal performance. This innovative construction method results from the synergy between computational geometry, robotic fabrication, operations research, and circular economy principles. Foam Injection Molding Machine

OctaFoam prototype – outside view

hot-wire cutting of EPS foam using a robotic system

host: Southeast University Nanjing | @southeast.university – ETH Zurich | @ethzurich

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

Eps a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.